Understanding the Aluminum Composite Panel Production Line

The Aluminum Composite Panel Production Line is an essential component in the manufacturing of modern construction and decoration materials. Aluminum composite panels, known for their lightweight, durability, and versatile design options, are widely used in both interior and exterior applications. This article explores the basic structure and operation of such production lines.

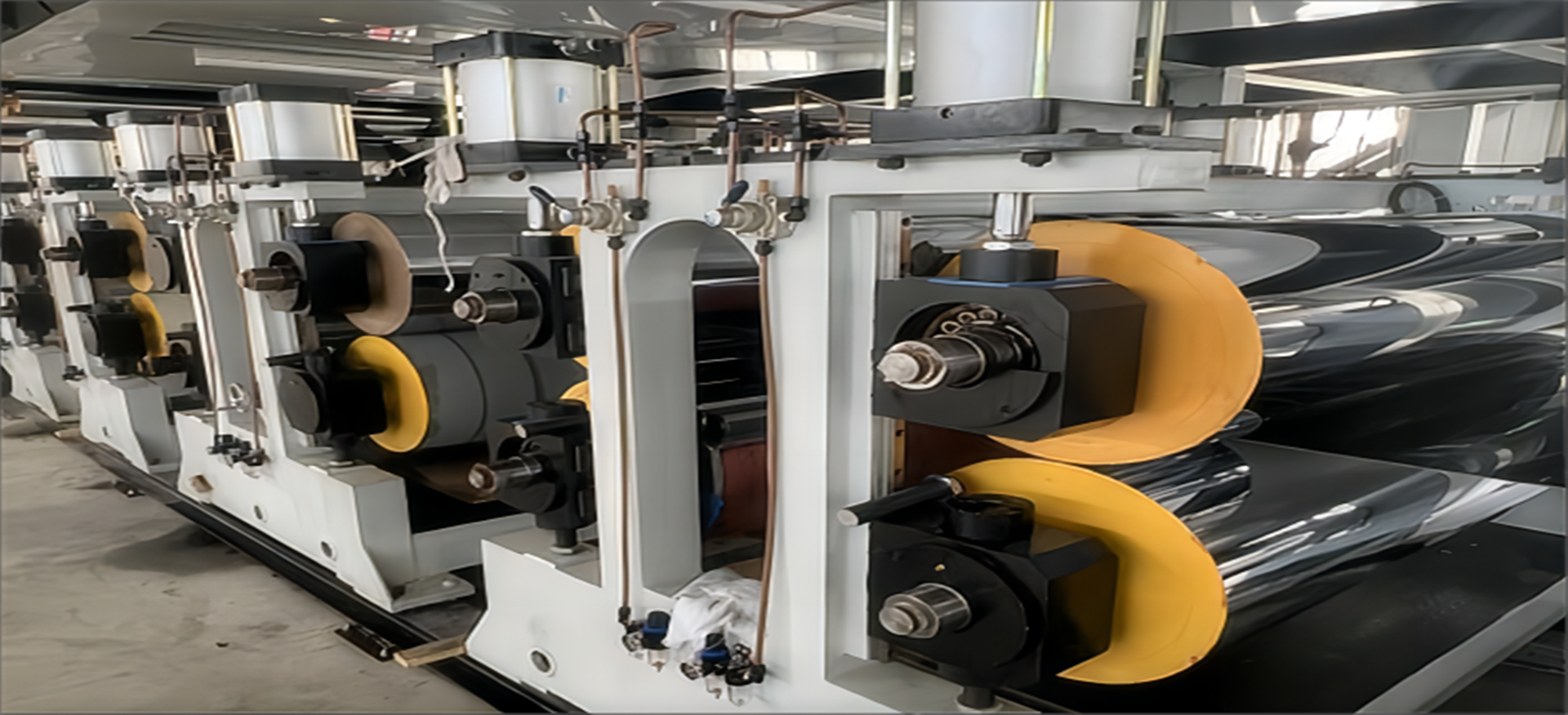

A typical aluminum composite panel production line consists of various segments, including a coil unwinding system, a pre-treatment unit, a lamination process, and a cutting unit. The process begins with aluminum coils being fed into the machine, where they are cleaned and pre-treated to ensure strong adhesion of the core material. The core material, often polyethylene or mineral-filled plastic, is then fused between two layers of aluminum sheets during the lamination stage.

Temperature control and pressure management are critical during this process, as they directly affect the bonding quality. The laminated panels then pass through a cooling system and are trimmed to the desired dimensions. This streamlined process ensures the production of panels that meet high standards for precision and quality.

The aluminum composite panel production line has significantly evolved over the years. Today’s systems are equipped with advanced automation features, which enhance efficiency and reduce labor requirements. Additionally, many lines now incorporate eco-friendly measures, such as waste recycling systems, reflecting the growing emphasis on sustainable manufacturing.

The versatility of aluminum composite panels makes them suitable for various industries, including architecture, signage, and transportation. The production line’s ability to meet diverse requirements, such as custom colors and surface finishes, is a key factor in their widespread adoption.

https://www.coating-line.com/product/acp-production-line.html

Application of Product and characteristics:

The final product ACP can be widely used in field of construction decoration such as curtain wall, interior and exterior wall of building,ceiling,column,storefront,billboard,exhibition rack,and auto etc.

1.High capacity and various thickness from 1mm to 8mm ;

2.The thickness range of Aluminum coil covers 0.018mm-0.5mm ;

3.Can use recycled PE ;

4.Stable technics and easy operation;

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness