Key Features to Consider When Choosing Extension Drilling Tools

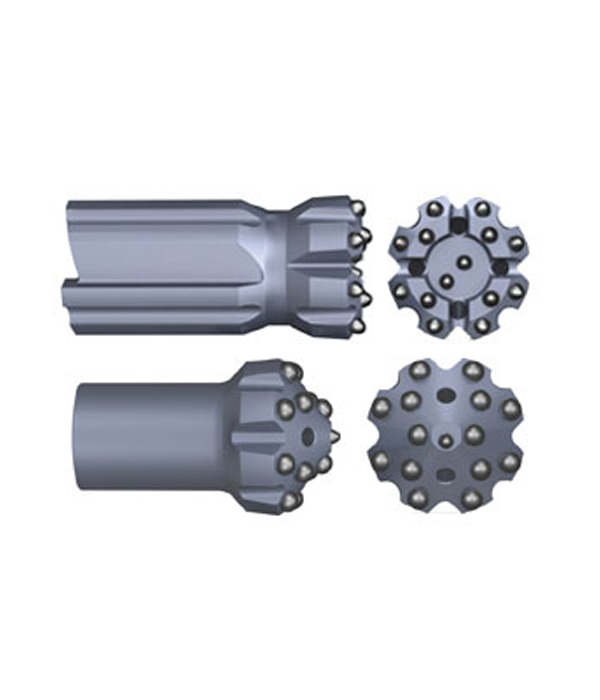

Choosing the right Extension Drilling Toolsfor your project requires careful evaluation of several factors beyond simple length or cost. Each component plays a role in determining the success and efficiency of the drilling operation.

One important feature is thread design. The threads must ensure tight, secure connections while allowing for easy assembly and disassembly in the field. Poorly designed threads can lead to early failure, compromised safety, or vibration during use.

Material composition is another key factor. Extension rods should be made from high-strength, fatigue-resistant steel. This is especially critical in high-impact applications such as bench drilling or underground mining, where tools are subjected to repeated dynamic stress.

Rod diameter and internal flushing options are also important. Some applications benefit from rods with internal water or air flushing systems, which help remove debris from the borehole and keep the bit cool. This improves drilling performance and reduces bit wear.

Additionally, surface treatment—such as nitriding or hard chrome plating—can improve wear resistance and reduce friction. These features contribute to longer service life and better performance in abrasive environments.

Finally, consider logistical aspects such as weight, transportability, and field handling. A good extension drilling tool should not only perform reliably but also be easy to integrate into the operational workflow without requiring extensive modifications.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness