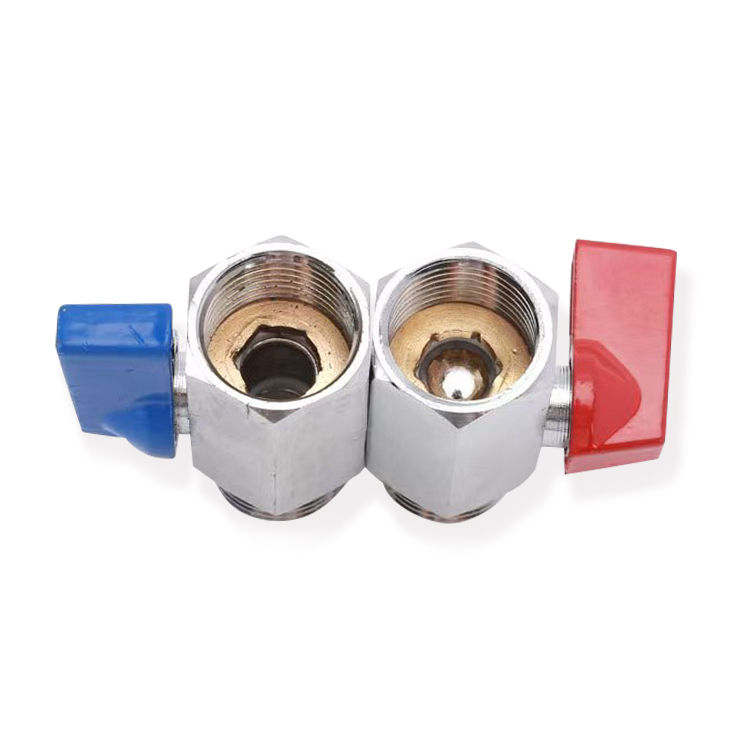

Common Challenges Faced with Mini Valves and How to Address Them

Mini valves are essential components in many mechanical and fluid control systems, yet they can present several challenges that affect performance and longevity. One common issue with mini valves is leakage, which can arise from wear and tear of internal seals or improper installation. Leakage not only reduces system efficiency but may also cause safety concerns depending on the fluid type.

Another pain point is clogging, especially when mini valves are used in systems with particles or debris in the fluid. Over time, these impurities can block valve mechanisms, leading to malfunction or slower response times. Regular maintenance and filtration are crucial steps to mitigate this problem.

Durability is also a concern for users, as mini valves often operate in harsh environments with temperature fluctuations or corrosive substances. Selecting materials that withstand these conditions is important to prevent early failure. Additionally, some mini valves might require complex adjustments or specialized tools, which could complicate installation and repair.

Users increasingly demand mini valves that offer precise control while maintaining compactness. They seek valves that integrate smoothly into systems without adding bulk, yet provide reliable sealing and long service life. Easy installation and minimal maintenance are also priorities to reduce downtime.

In summary, addressing leakage, clogging, and durability issues while meeting user expectations for compactness and reliability remains a focus for manufacturers and system designers. Understanding these pain points helps users select appropriate mini valves and plan maintenance to ensure consistent operation.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness