Exploring the Role of PET Film in Metallic Decorative Film Performance

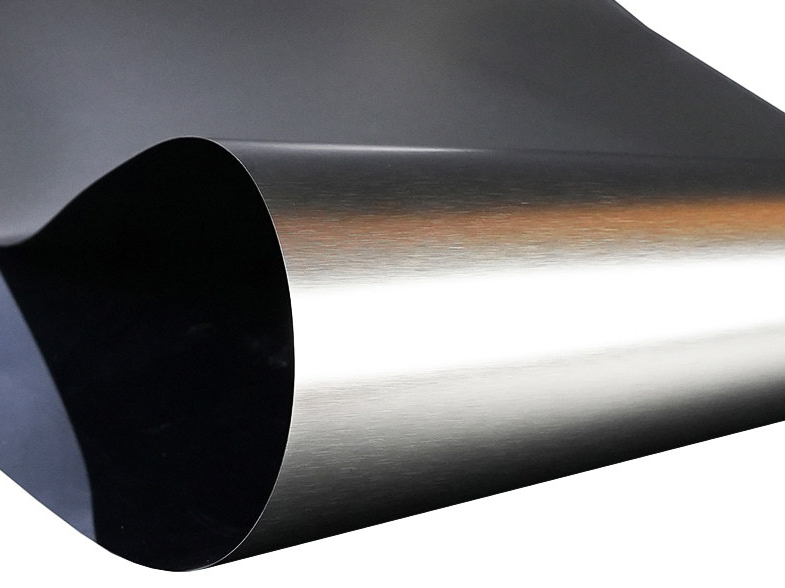

Metallic Decorative Film has become a preferred material in interior decoration, product finishing, and architectural applications, largely due to its practical surface structure and visual appeal. One of the essential components in the production of this film is PET (polyethylene terephthalate) film, which contributes to both the appearance and durability of the final product.

The use of PET film as the surface layer in Metallic Decorative Film provides several functional advantages. Known for its smooth and stable surface properties, PET helps create a uniform metallic finish with consistent color and texture. This ensures that the decorative film delivers a clean, refined appearance across a variety of applications, from furniture panels to wall coverings and product casings.

Another benefit of using PET film is its resistance to common surface damage such as light scratches and stains. While no material is completely immune to wear, PET’s surface characteristics help minimize the appearance of minor abrasions, contributing to a longer-lasting, attractive finish for the underlying metallic layer.

In addition to protection, PET film offers excellent clarity and transparency, making it suitable for films that require both decorative and functional features. In Metallic Decorative Film, this clarity allows the metallic ink or foil beneath the PET layer to display its reflective quality effectively, producing a smooth and visually balanced metallic effect without distortion.

The flexibility of PET film also enhances the application process of Metallic Decorative Film. It can conform to flat, curved, or slightly textured surfaces, maintaining strong adhesion and a consistent appearance. This makes it a versatile option for covering different substrates such as wood, plastic, metal, and glass, commonly found in both residential and commercial settings.

Furthermore, PET film is valued for its easy maintenance. Surfaces covered with Metallic Decorative Film using PET are typically simple to clean with a soft cloth and mild cleaning agents, helping retain their appearance over time without complicated care routines.

In conclusion, the inclusion of PET film in the surface structure of Metallic Decorative Film improves its durability, visual quality, and application versatility. This combination makes it a practical and attractive material choice for various decorative and protective surface applications.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness