What are some common applications of China spot welders in the automotive industry?

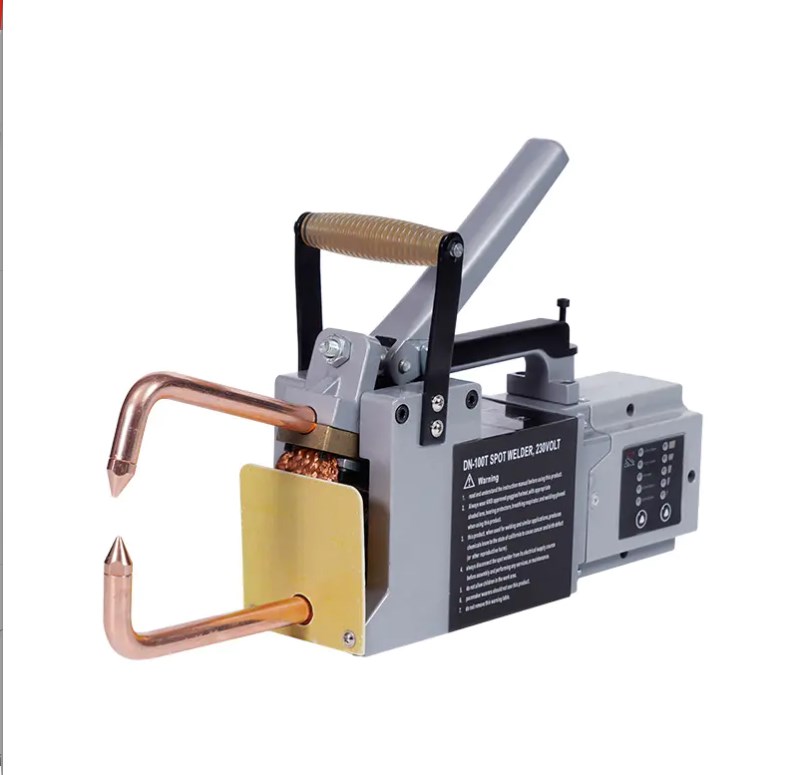

China spot welders have gained recognition for their efficiency and reliability in various industrial sectors, particularly in automotive manufacturing. With a focus on energy efficiency, regulatory compliance, and diverse applications, these machines stand out as integral components in modern production lines.

Energy efficiency is a paramount consideration in welding technology, and China spot welders excel in this aspect. Compared to traditional welding methods, such as arc welding, spot welding requires less energy consumption due to its localized heat application. China spot welders leverage advanced technology to optimize energy usage, ensuring minimal waste and cost-effectiveness in operations.

In the automotive industry, China spot welders play a pivotal role in assembling vehicle components. Their ability to create strong, precise welds in a fraction of the time makes them indispensable for joining sheet metal parts like body panels, frames, and chassis components. This process ensures structural integrity and enhances the overall safety and durability of automobiles.

Moreover, China spot welders contribute to streamlining production processes, increasing throughput, and reducing manufacturing time. In automotive assembly lines, where efficiency is paramount, these machines enable seamless integration into robotic systems for automated welding operations. This synergy between human expertise and robotic precision enhances productivity while maintaining consistent weld quality.

However, alongside performance benefits, compliance with regulations and certifications is essential for ensuring product quality and safety. China spot welders must adhere to industry standards and regulations governing welding equipment, such as ISO 9001 and CE certifications. These certifications validate the adherence to quality management systems and safety standards, assuring customers of the reliability and performance of China spot welders.

In summary, China spot welders combine energy efficiency, versatility, and regulatory compliance to meet the demands of modern manufacturing, particularly in the automotive industry. With their widespread applications and technological advancements, these machines continue to shape the landscape of welding technology, driving efficiency, and innovation in production processes. As industries evolve, China spot welders remain at the forefront, delivering precise, reliable welds while adhering to stringent quality and safety standards.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness