The Art of Fan Blade Mold Manufacturing

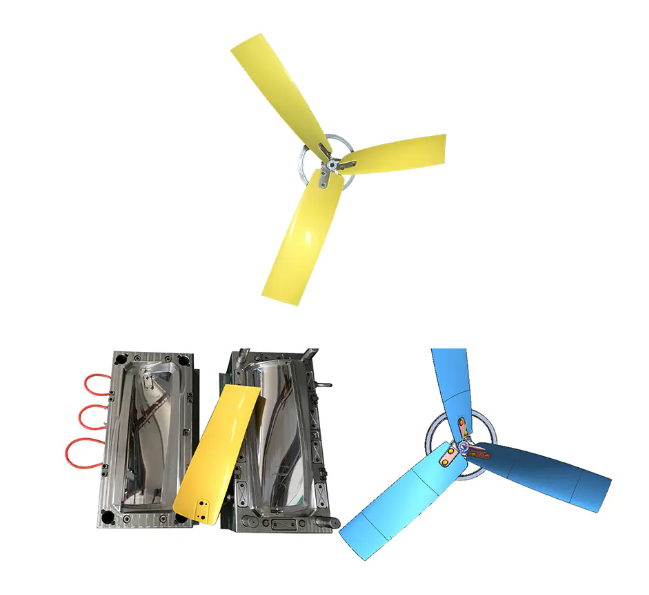

Fan blades are a critical component in various industries, from aviation to home appliances, and their production relies heavily on the precision and quality of fan blade molds. These molds are designed to produce blades with specific aerodynamic properties that optimize performance and efficiency. The manufacturing process for fan blade molds is a testament to the precision engineering and advanced materials science that underpin modern manufacturing techniques.

The design of a fan blade mold begins with a thorough understanding of the intended application of the fan. Engineers must consider factors such as the speed of rotation, the volume of air to be moved, and the environmental conditions in which the fan will operate. This information is used to create a mold that will produce blades with the optimal shape and balance for the task at hand.

Once the design is finalized, the mold is crafted from high-quality materials that can withstand the pressures and temperatures of the injection molding process. The mold must be able to produce blades with a high degree of consistency, as even minor variations can affect the performance of the fan.

The injection molding process for fan blades involves heating a plastic or metal material until it becomes molten, then injecting it into the mold under high pressure. As the material cools and hardens, it takes on the shape of the mold, creating a fan blade with the desired contours and features. The finished blades are then removed from the mold, inspected for quality, and prepared for assembly.

Fan blade molds are not only used for mass production but also for prototyping and testing new designs. This allows manufacturers to iterate on their designs quickly and efficiently, ensuring that the final product meets the highest standards of performance and reliability.

In conclusion, fan blade molds are a critical component in the production of high-quality fans. They enable manufacturers to produce blades with precision and consistency, ensuring that fans operate efficiently and effectively in their intended applications. As technology continues to advance, the role of fan blade molds in the manufacturing process will remain essential, driving innovation and improving the performance of fans across a wide range of industries.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness