The Dynamics of Extruder Pellet Machine Extrusion Speed: A Comprehensive Analysis

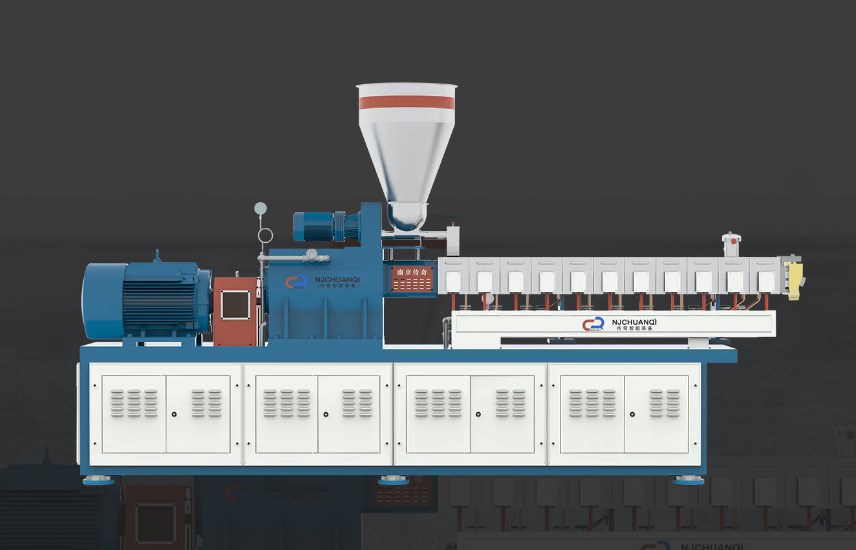

The Extruder Pellet Machine is a critical component in the plastics and recycling industries, where it plays a pivotal role in converting raw materials into pellets. The speed at which an Extruder Pellet Machine operates is a topic of significant interest, as it directly impacts production efficiency and output. This article delves into the various factors that influence the extrusion speed of Extruder Pellet Machines and how they can be optimized for maximum performance.

The extrusion speed of an Extruder Pellet Machine is determined by a complex interplay of mechanical, thermal, and material properties. The machine's screw design, for instance, is a key factor that affects how quickly the material can be melted and extruded. A well-designed screw can handle higher throughputs without compromising the quality of the final product. The material being processed also plays a crucial role; different polymers have different melting points and viscosities, which in turn affect the speed at which they can be extruded.

Thermal management within the Extruder Pellet Machine is another critical aspect that influences extrusion speed. The temperature profile along the barrel and the die must be carefully controlled to ensure that the material is melted uniformly and does not degrade. Overheating can lead to material degradation, while underheating can result in poor melt quality and lower extrusion speeds. Therefore, precise temperature control systems are essential to maintain the optimal conditions for efficient extrusion.

The die design of the Extruder Pellet Machine also has a significant impact on extrusion speed. The die's geometry and the number of holes determine the flow rate of the molten polymer. A well-designed die can help achieve higher extrusion speeds by minimizing pressure drops and ensuring a uniform flow of material. Additionally, the use of advanced materials and coatings on the die can improve heat transfer and reduce wear, further enhancing the machine's performance.

The drive system of the Extruder Pellet Machine, including the motor and gearbox, must be capable of providing the necessary torque and speed to handle the demands of high-speed extrusion. Modern variable frequency drives (VFDs) allow for precise control of the motor speed, enabling operators to fine-tune the extrusion process to achieve the desired output. The robustness of the drive system is also crucial, as it must withstand the high loads and temperatures associated with continuous operation.

Another factor to consider is the quality of the raw material being fed into the Extruder Pellet Machine. Contaminants, such as moisture or impurities, can significantly affect the extrusion process. Drying systems and filtration equipment are often used to precondition the material, ensuring that it is in the optimal state for extrusion. This not only improves the extrusion speed but also the quality of the final product.

Maintenance and upkeep of the Extruder Pellet Machine are also essential for maintaining optimal extrusion speeds. Regular cleaning and inspection of the machine can prevent blockages and wear, which can otherwise lead to reduced efficiency and slower extrusion speeds. The use of high-quality spare parts and lubricants can also contribute to the longevity and performance of the machine.

In conclusion, the extrusion speed of an Extruder Pellet Machine is a multifaceted issue that involves a careful balance of machine design, material properties, thermal management, and operational practices. By understanding and optimizing these factors, manufacturers can achieve higher extrusion speeds, leading to increased productivity and cost savings. The ongoing development of new technologies and materials will continue to push the boundaries of what is possible with Extruder Pellet Machine extrusion speeds, ensuring that these machines remain at the forefront of polymer processing technology.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness