Sustainability in Extrusion: Eco-Friendly Practices with Rubber Extruder Machines

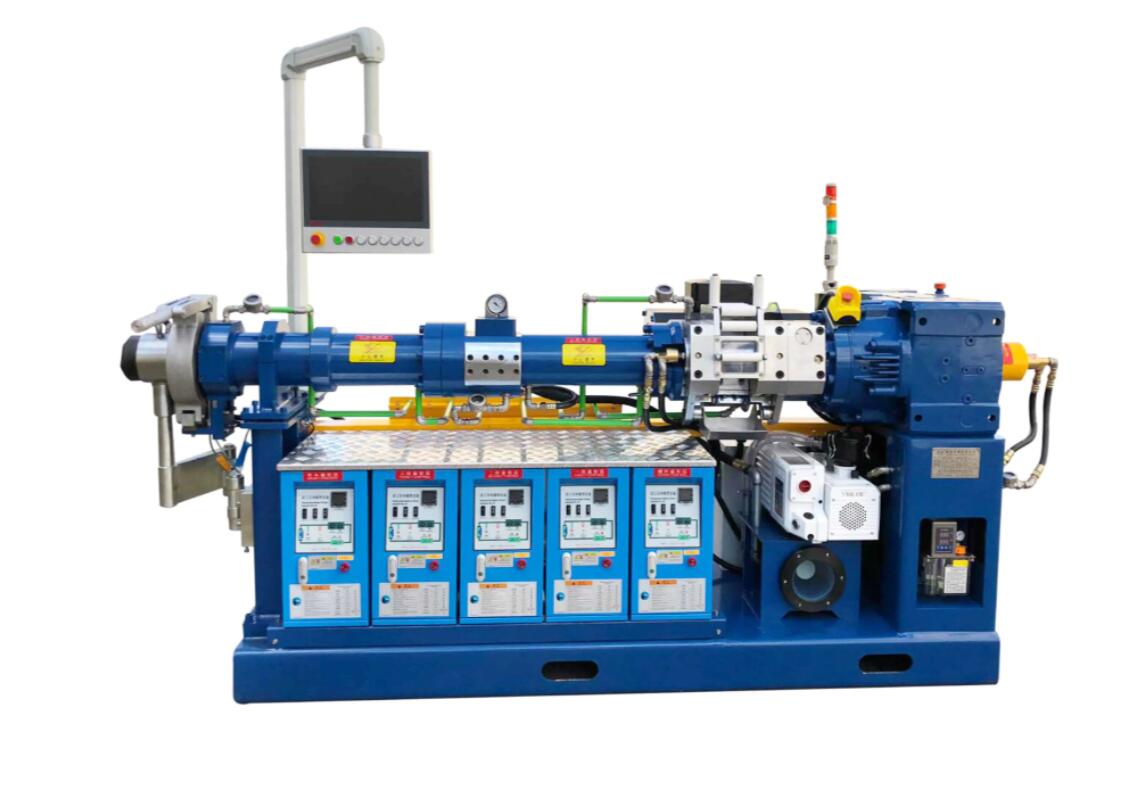

Rubber extrusion is a vital manufacturing process used to shape rubber materials into various forms for numerous industrial applications. The Rubber extruder machines is at the heart of this process, playing a crucial role in transforming raw rubber compounds into products such as seals, gaskets, hoses, belts, and other rubber-based components. These machines are designed to process both natural and synthetic rubbers, offering versatility and precision. This article outlines the essential features of a rubber extruder machine and their importance in the extrusion process.

Extruder Design and Construction

The design of a rubber extruder machine is tailored to handle the unique challenges presented by rubber processing. At the core of the machine is the screw, which plays an essential role in moving the rubber material through the barrel. The screw is often made of high-quality materials to withstand the intense mechanical stress and heat generated during the extrusion process. Additionally, the barrel, where the rubber is heated and molded, is constructed from durable materials like steel or special alloys to ensure longevity and resistance to wear.

The configuration of the barrel and screw can vary, with some extruders using a single screw, while others employ a twin-screw design. Twin-screw extruders are particularly useful for processing more complex compounds, as they allow for better mixing, dispersal of additives, and more uniform material flow.

Heating and Cooling Systems

A critical feature of any rubber extruder machine is its heating and cooling system, as controlling the temperature of the rubber is essential for achieving the desired properties in the final product. The rubber material needs to be heated to a specific temperature to soften and become pliable, allowing it to be formed into the desired shape. Conversely, once the rubber exits the extruder, it must be rapidly cooled to solidify and retain its new form.

Most rubber extruders are equipped with electric heaters or steam-heated systems to maintain consistent temperature levels along the barrel. The cooling system usually consists of water-cooled jackets around the barrel or specialized cooling zones to quickly solidify the extruded rubber.

https://www.zjbaina.com/product/rubber-extruders-series/150mm16d-20d-extrude-machine.html

1. Product name, specification model and equipment weight size:

1.1 Product Name: Cold Feed Extruder

1.2 Specification model: XJWP-120X20D

1.3 Equipment weight: about 5 tons

1.4 Dimensions (length X width X height): about 4200X1200X1600mm

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness