OEM cemented carbide inserts Manufacturer

Posted 2025-02-18 07:48:24

0

703

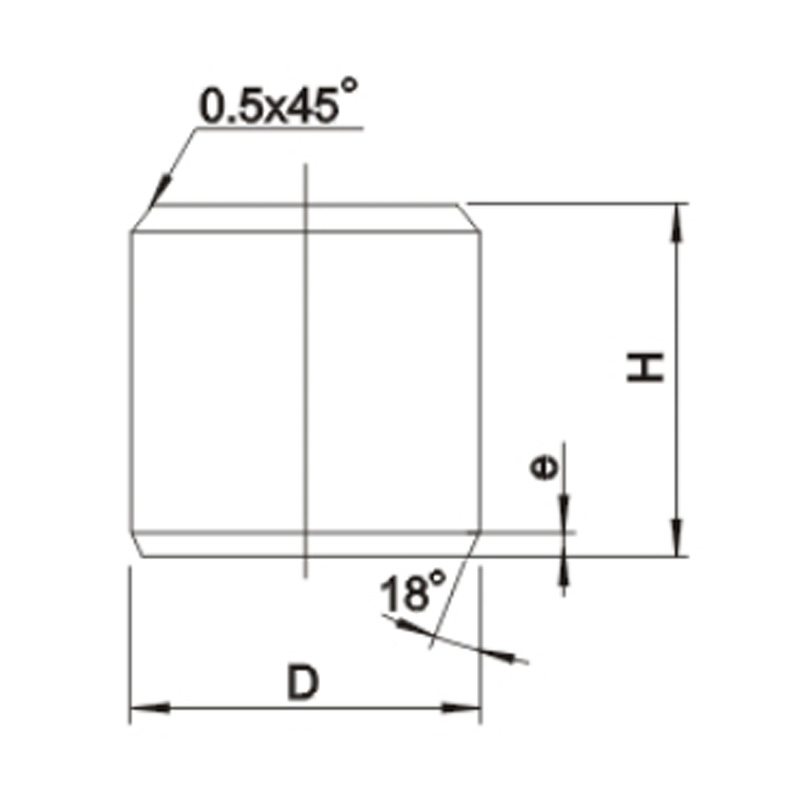

The versatility of cemented carbide inserts makes them a preferred choice for various machining operations. The combination of high hardness, wear resistance, and strength enables them to perform well in cutting tools that are used to machine a wide variety of materials, from metals to composites. As industries continue to push for higher productivity and precision, the role of cemented carbide inserts becomes even more significant. The development of advanced manufacturing techniques and the continued improvement of the material properties of cemented carbide inserts will only enhance their effectiveness in the future, making them indispensable to modern manufacturing processes.

Search

Categories

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Stamping Out Risk: Safety Strategies for Progressive Stamping Molds

Material handling is another area where safety must be prioritized in progressive stamping mold...

The Superiority of Brass Ball Bibcock in Modern Plumbing Systems

The brass ball bibcock stands as a cornerstone of durability and precision in plumbing...

Bottle Cap Torque Tester Ensuring Proper Seal Tightness and Quality Control

At Pacorr Testing Instruments, we offer the Bottle Cap Torque Tester, a highly effective tool for...

The Energy Efficiency Paradox of OEM NVMe SSD: Performance vs. Power Usage

In the rapidly evolving landscape of data storage technology, the OEM NVMe SSD has emerged as a...

Superior Performance and Design in Custom Cookware Sets

Our custom cookware sets are made from the highest quality materials, combining modern technology...