Users of Injection Moulded Pallets and Their Key Benefits

The rise of injection moulded pallets has been driven by their functionality, durability, and versatility, making them an attractive option for a variety of users. From manufacturers and logistics providers to retailers and distributors, these pallets are increasingly being adopted for their efficiency and long-term benefits.

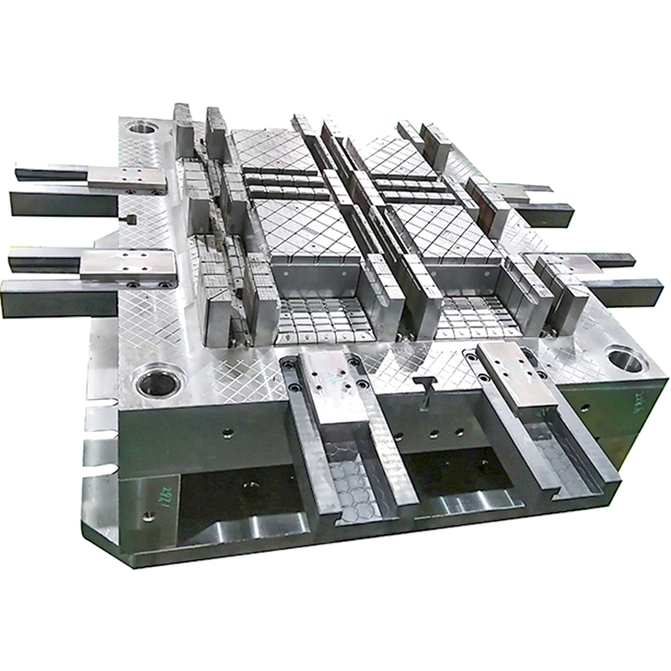

Manufacturers are one of the primary users of injection moulded pallets, particularly in industries where consistent and reliable material handling is essential. These pallets are used to transport raw materials, components, and finished products through the production process and to storage facilities. The strength and durability of injection moulded pallets allow manufacturers to handle heavy or bulky items without concern for pallet failure. Additionally, the ability to customise the design of these pallets for specific purposes is a major advantage for manufacturers who need specialised solutions to fit their operational needs.

Logistics companies also rely heavily on injection moulded pallets for their material handling operations. Whether they are dealing with large volumes of goods or transporting delicate items, these pallets are designed to meet a range of logistical challenges. Their stackability and ease of handling allow logistics providers to maximise storage space in warehouses and transport vehicles, ensuring efficient use of available resources. The durability of injection moulded pallets reduces the likelihood of product damage during handling, making them a preferred choice in the logistics industry.

In the retail sector, injection moulded pallets are widely used for both in-store displays and stock organisation in warehouses. Retailers use these pallets to transport goods from the back of the store to the sales floor, as well as to manage inventory in storage areas. The ability to easily clean and maintain injection moulded pallets is important for retailers, especially when handling products that require strict hygiene standards, such as food items or health-related products.

The food and beverage industry is another key user of injection moulded pallets, as hygiene and contamination control are critical in these sectors. These pallets are made from non-porous materials, making them resistant to moisture and bacteria, which helps maintain the safety and quality of food and beverages during transport and storage. Additionally, their lightweight nature and durability make them suitable for environments that involve frequent handling or washing.

Environmental-conscious users also appreciate the sustainability benefits of injection moulded pallets. Many of these pallets are made from recyclable materials, contributing to reduced waste and a lower environmental impact. The longevity of injection moulded pallets also means that they need to be replaced less frequently, making them a cost-effective and eco-friendly option in the long run.

In summary, injection moulded pallets are widely used across different sectors, from manufacturing and logistics to retail and food industries. Their durability, hygiene features, and customisation options make them a valuable asset for users seeking reliable, efficient, and cost-effective material handling solutions.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness