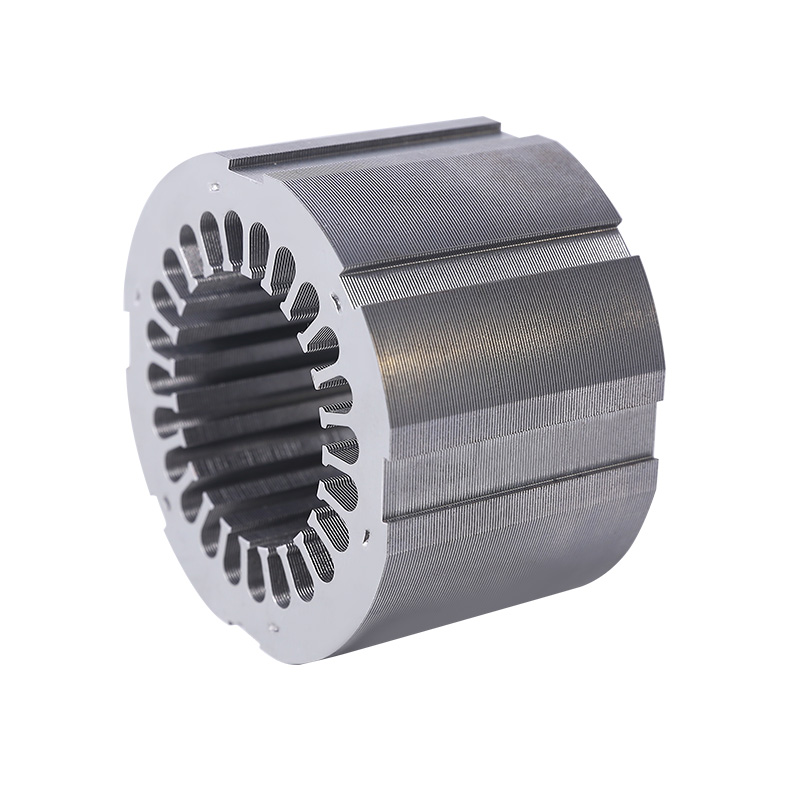

Custom Metal Mold: Engineered for Exceptional Durability and Longevity

Custom Metal Mold stands as a cornerstone of industrial manufacturing, offering unparalleled durability and longevity to meet the rigorous demands of high-volume production. Designed to withstand extreme operational stress, Custom Metal Mold integrates advanced engineering principles and premium materials to deliver consistent performance across hundreds of thousands—or even millions—of cycles.

A defining feature of Custom Metal Mold is its superior fatigue resistance. Constructed from high-grade tool steels such as H13, S136, or P20, combined with precision heat treatment processes, Custom Metal Mold maintains structural integrity under repetitive mechanical and thermal loads. This ensures minimal deformation over time, even in high-pressure applications like die casting or injection molding. For industries requiring mass production of automotive components, consumer electronics, or precision machinery parts, Custom Metal Mold guarantees reliability and dimensional stability across extended production runs.

Complementing its fatigue resistance is the ease of maintenance inherent in Custom Metal Mold. Utilizing modular design principles, critical wear-prone components—such as ejector pins, inserts, and sliders—are engineered for quick replacement without dismantling the entire mold. This modularity significantly reduces downtime during maintenance, enabling manufacturers to resume production swiftly. Additionally, Custom Metal Mold’s compatibility with standardized parts streamlines inventory management and lowers long-term operational costs.

Custom Metal Mold further enhances longevity through customizable surface treatments. Techniques like nitriding, chrome plating, or DLC (Diamond-Like Carbon) coatings are applied to critical areas to bolster hardness, corrosion resistance, and wear protection. These treatments ensure that Custom Metal Mold retains its precision even in abrasive or high-temperature environments, such as rubber molding or thermoplastic processing.

For industries prioritizing sustainability and cost-efficiency, Custom Metal Mold offers a compelling value proposition. While the initial investment may be higher than conventional alternatives, its extended lifespan and reduced maintenance requirements translate to lower per-unit costs over time. By minimizing unplanned downtime and material waste, Custom Metal Mold optimizes production efficiency and supports lean manufacturing practices.

In summary, Custom Metal Mold is not merely a tool but a strategic asset for businesses aiming to achieve high-output, high-consistency manufacturing. Whether for automotive, aerospace, or consumer goods, Custom Metal Mold delivers the resilience, adaptability, and precision required to thrive in competitive industrial landscapes. Choose Custom Metal Mold to future-proof your production capabilities and maximize ROI.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness