Understanding the Production Process of Plastic Bucket Cap Moulds

Plastic injection bucket cap moulds are essential for producing durable, secure, and functional caps for plastic buckets. These caps are used in diverse sectors, including food and beverage, chemicals, pharmaceuticals, and even industrial products. This article will explore the key aspects of plastic injection bucket cap moulds, how they work, and their impact on manufacturing processes across different industries.

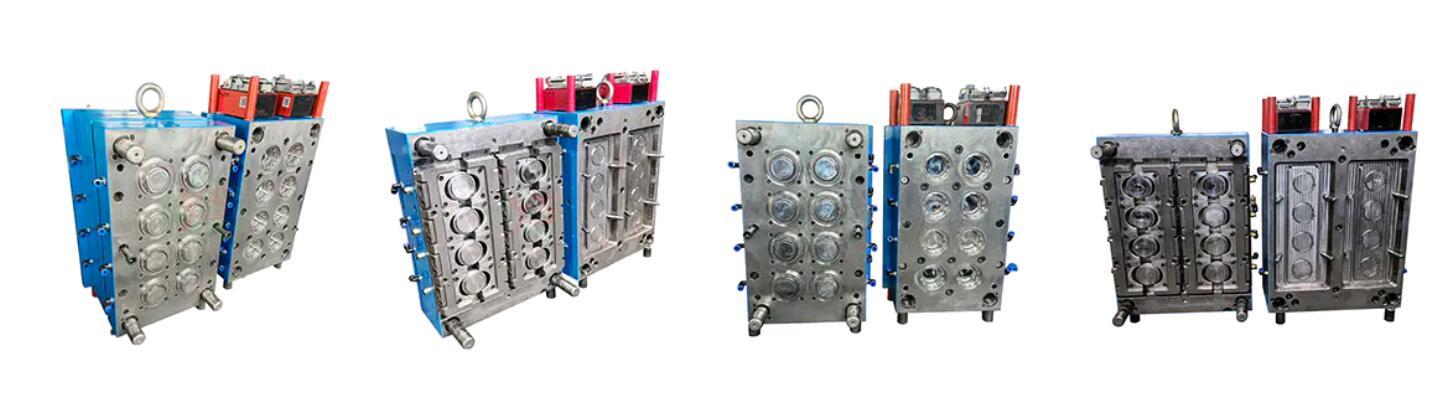

A plastic injection bucket cap mould is a specialized tool designed to form the lids or caps that fit securely on plastic buckets. These moulds are designed to produce bucket caps with high precision, ensuring a tight seal to prevent leakage and contamination. Plastic bucket caps typically come in various designs, such as screw-on, snap-on, or flip-top lids, depending on the intended use and the specific requirements of the product being packaged.

The mould itself is typically made from durable materials such as steel or aluminum, which are capable of withstanding the high temperatures and pressures involved in the injection moulding process. The precision and complexity of the mould are crucial factors in determining the quality and functionality of the final product.

The plastic injection moulding process begins by melting plastic pellets or granules in a heated barrel, turning the plastic into a liquid state. The molten plastic is then injected into the mould cavity under high pressure. Once the plastic fills the mould, it is allowed to cool and solidify, taking the shape of the bucket cap. The mould is designed to allow for easy ejection of the finished product once it has cooled sufficiently.

The entire process is highly automated and controlled by advanced computer systems that regulate temperature, pressure, and timing. This ensures that each cap produced is uniform in shape and size, meeting the exact specifications required by the customer.

https://www.ysmou.com/product/cap-mould/plastic-injection-bucket-cap-mould-with-antitheft-ring.html

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic motor, requiring manual installation without much effort.

During the processing, we strictly control each step and test to ensure product quality and delivery time. After each sample is confirmed by the customer for quality, it is arranged for shipment.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness