Enhancing Manufacturing Precision with Rotary Transfer Machine Servo

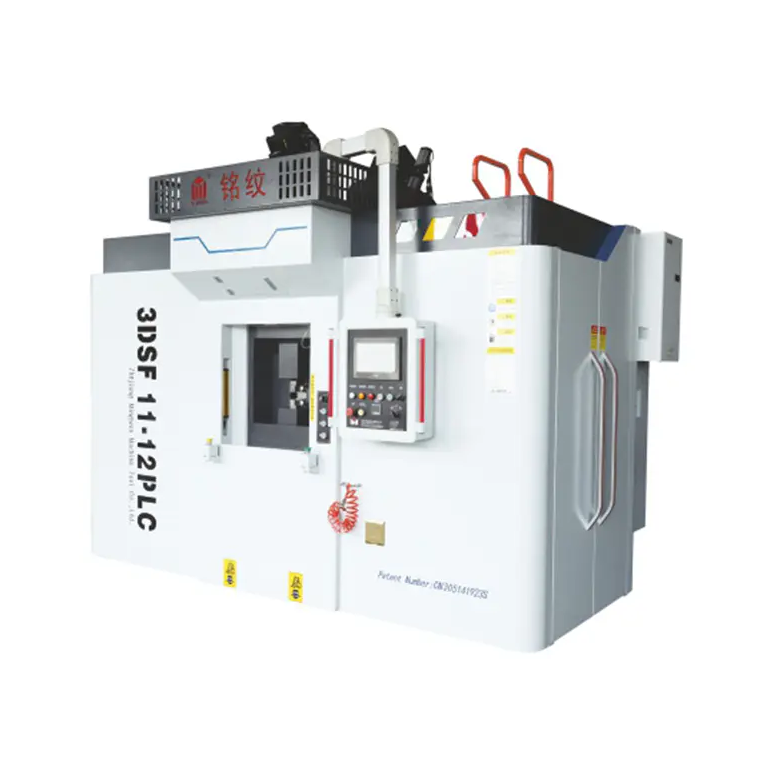

The integration of servo technology in rotary transfer machines is redefining the approach to multi-station machining. These systems rely on precise rotational and linear control, allowing for consistent material handling and synchronized operations at each station. The servo-driven rotary transfer machine combines mechanical stability with digital adaptability, leading to enhanced reliability in demanding production environments.

In a Rotary Transfer Machine Servo, components are typically transferred in a circular path, stopping at designated stations for operations such as drilling, milling, or tapping. The use of servo motors at key points in the system enables each station to perform with greater repeatability and reduced cycle time. The programmable nature of servo systems allows engineers to fine-tune movements without modifying the machine structure, offering valuable flexibility in applications that require frequent part changes.

Servo integration also supports advanced feedback mechanisms. Sensors relay position and velocity data to the control system in real time, ensuring smoother transitions and minimizing misalignments. This reduces the rate of rejected parts and enhances the longevity of the tooling and machine components.

Rotary transfer systems equipped with servos are particularly suited for medium to high-volume manufacturing scenarios. Industries producing automotive components, precision valves, or small fittings benefit from the machine's ability to perform multiple operations in a compact layout. Servos contribute to reducing the overall machine footprint while maintaining throughput and dimensional stability.

Unlike older systems that depend heavily on cam-driven mechanics, servo-based platforms support updates through software alone. This aspect is vital for manufacturers seeking to accommodate design changes or improve production efficiency without large-scale mechanical alterations.

Moreover, the energy efficiency of servo motors contributes to reduced operational costs. Their controlled acceleration and deceleration minimize energy spikes and wear on mechanical parts. This aspect, combined with intelligent diagnostics, makes the rotary transfer machine with servo capabilities a viable solution for consistent part quality across extended runs.

As servo systems continue to evolve, their role in rotary transfer machines is likely to expand, offering more responsive motion control and tighter process integration. Manufacturers aiming to improve cycle consistency and setup agility often turn to servo-enhanced rotary solutions to meet their evolving requirements.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness