Precision Machining with High Speed Steel Twist Drills

High Speed Steel twist drills have long been a dependable tool in precision engineering environments. Their balance between toughness and hardness makes them suitable for a wide variety of materials, including low to medium carbon steels, aluminum, and some plastics. The durability of HSS enables it to withstand higher temperatures than carbon steel tools, allowing prolonged use without significant wear.

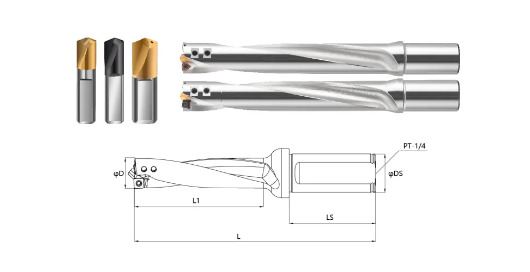

These drills typically feature a helical flute design, which aids in efficient chip removal while maintaining steady contact with the workpiece. This design not only improves cutting action but also reduces the chances of bit wandering during operation. Such reliability contributes to consistent hole dimensions, a vital factor in applications requiring strict tolerances.

In machining operations where rigidity and dimensional stability are essential, the HSS twist drill provides predictable performance. Although newer materials such as carbide offer higher speed capabilities, HSS remains widely used due to its resilience and affordability. It also accommodates re-sharpening, extending its usefulness over time.

Operators often choose HSS twist drills when flexibility and moderate cutting speed are desired. Their shock-resistant nature makes them ideal for handheld drilling as well as machine setups where feed rates may vary. In addition, their compatibility with standard drill presses and manual tools makes them a common fixture in small-scale workshops and repair facilities.

Coated variants, such as those treated with black oxide or titanium nitride, further enhance their usability by reducing friction and extending tool life. However, even uncoated HSS twist drills provide satisfactory performance in many general-purpose applications.

Despite the evolution of cutting tool materials, HSS twist drills continue to serve a reliable role in various industries. Their adaptability, coupled with ease of maintenance, keeps them relevant in both educational settings and professional manufacturing environments. As a result, they remain a staple in any toolkit focused on precision and reliability without unnecessary complexity.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness