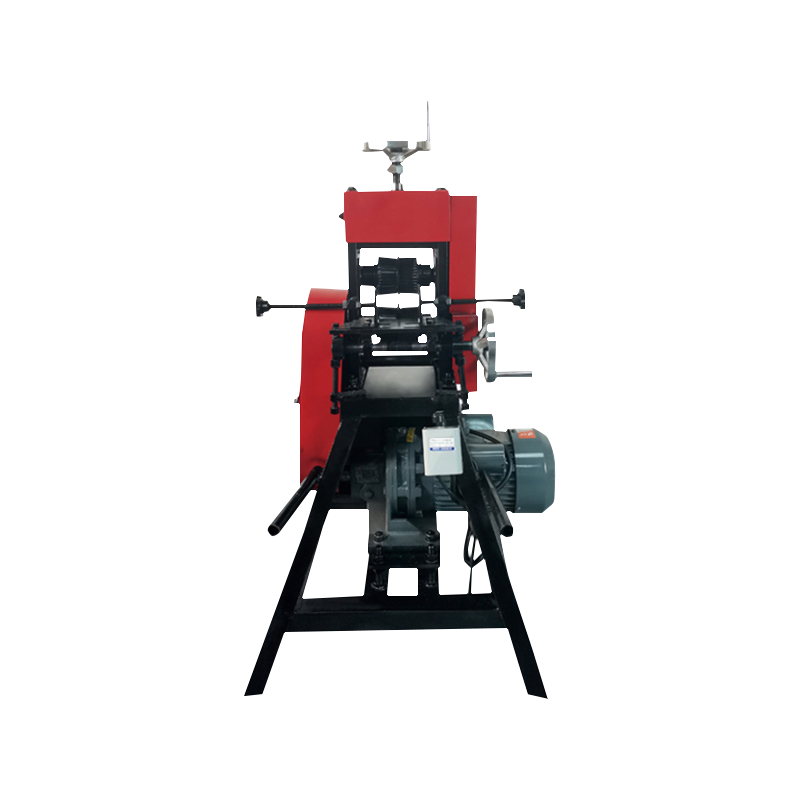

Adjustable Stripping Depth and Width: Precision Control with the Vertical Electric Stripping Machine

A key feature that sets the vertical electric stripping machine apart is its highly adjustable stripping depth and width, designed to meet the demands of diverse cable types and sizes. This flexibility ensures that the insulation is removed perfectly—completely stripping the outer layer without causing any damage to the delicate wire core inside.

The adjustable settings of the vertical electric stripping machine allow operators to tailor the stripping process precisely according to the wire diameter and insulation thickness. Whether working with thin, delicate cables or thicker, heavily insulated wires, the machine can be calibrated to strip only the required amount of material. This prevents accidental cutting or nicking of the conductive core, which could compromise the wire’s integrity and performance.

Thanks to this feature, the vertical electric stripping machine supports a wide range of cables, from fine electronics wiring to larger power cables. Users can easily adjust the stripping parameters through intuitive controls or digital interfaces, making it simple to switch between different wire types without downtime. This adaptability increases workflow efficiency and reduces errors.

By maintaining the integrity of the wire core, the vertical electric stripping machine enhances the quality and reliability of subsequent electrical connections or recycling processes. Clean, precise stripping leads to better conductivity and safer, more durable installations.

Furthermore, the precise control over stripping dimensions minimizes material waste and improves cost efficiency. Operators can trust the machine to deliver consistent results, part after part, batch after batch.

In conclusion, the adjustable stripping depth and width of the vertical electric stripping machine provide unparalleled versatility and precision. This feature ensures the machine can handle a broad spectrum of wire types while protecting the core material, making it an indispensable tool in any wire processing or manufacturing environment. For reliable, damage-free stripping, the vertical electric stripping machine is the top choice.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness