Medical Syringe Moulds: The Path to High-Volume Production

Medical syringe moulds can accommodate a variety of materials, including medical-grade plastics like polypropylene (PP), polycarbonate (PC), or high-density polyethylene (HDPE). These materials are chosen for their durability, biocompatibility, and ability to be molded into precise shapes. The versatility of molds to handle different materials ensures that syringes can be produced with the required strength and safety features, depending on the intended use.

Injection molding with high-quality medical syringe molds enables manufacturers to produce syringes quickly and efficiently. The molding process is fast, with the ability to produce multiple parts in each cycle. This rapid production speed ensures that manufacturers can meet the high demand for syringes, especially during times of increased medical need, such as during vaccination campaigns or in response to pandemics.

Automated production using syringe molds reduces the risk of human error, which can occur in manual or less precise manufacturing processes. Once the mold is set up, the production process is largely automated, leading to fewer defects and ensuring that each syringe produced is uniform and free from errors.

Modern syringe molds are designed to minimize material waste during production. The efficiency of the injection molding process ensures that the maximum amount of material is used for the syringe parts, reducing scrap and waste. Additionally, the ability to recycle materials further contributes to the environmental sustainability of the production process.

Medical syringe molds are essential in the production of various types of syringes for different medical applications. Some common applications include:

Vaccination Syringes: Syringes used for injecting vaccines need to be manufactured with precise measurements to ensure accurate dosing.

Insulin Syringes: For diabetic patients, insulin syringes are designed with smaller, precise graduations to deliver accurate doses of insulin.

Intravenous Syringes: These syringes are used in hospitals and clinics for administering medications through intravenous lines.

Specialty Syringes: Syringes with safety features, such as retractable needles or self-sealing mechanisms, are increasingly being produced using specialized syringe molds.

Syringes for Medical Testing: Syringes used for blood sampling or diagnostic tests require careful design to prevent contamination and ensure accuracy.

https://www.ysmou.com/product/medicine-mould/injection-medical-syringe-mould.html

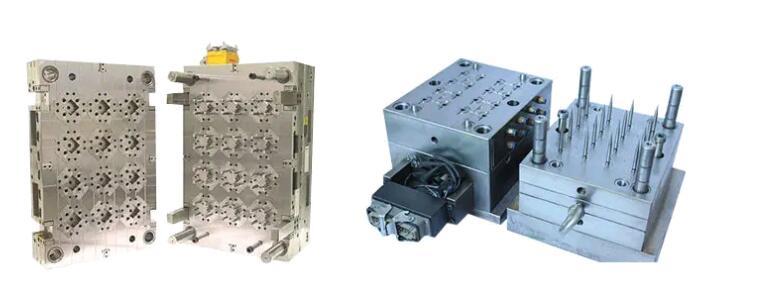

Core slider: Luer interface slider system

Gate type: hot runner point gate

Product plastic: TPE or medical PVC (if using PVC, I

We do not recommend the use of thermal guides)

Cavity Core Polishing: Mirror Polishing

Needle plug plug mold structure: using the insert method to make it set

On the mold base, the same parts in the mold can be mutually

Changed.

Syringe tight plug die life: at least 5 million mode

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness