"Troubleshooting Common Defects in Yogurt Cup Injection Moulding"

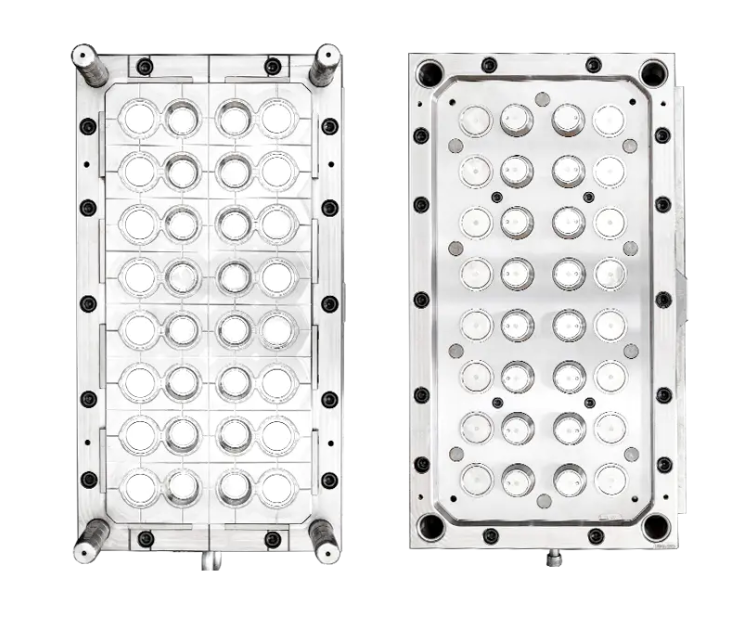

The yogurt cup injection mould plays a crucial role in the modern food packaging industry, providing a reliable and efficient solution for producing high-quality yogurt cups. Whether you are a small-scale producer or a large manufacturing company, the yogurt cup injection mould offers a range of benefits that can significantly enhance your production process and product quality.

One of the primary advantages of the yogurt cup injection mould is its precision and consistency. These moulds are engineered to produce yogurt cups with uniform thickness and shape, ensuring that each cup meets the highest standards of quality. This precision not only enhances the appearance of the product but also ensures that the cups are strong and reliable, capable of withstanding the rigors of transportation and storage.

Another significant benefit of the yogurt cup injection mould is its efficiency. The process of injection moulding allows for rapid production, with the ability to create large quantities of yogurt cups in a short amount of time. This high-speed production capability is essential for meeting the demands of a growing market, ensuring that you can keep up with consumer needs without compromising on quality.

The yogurt cup injection mould also offers a high degree of customization. Producers can choose from a variety of designs, sizes, and colors to create yogurt cups that perfectly match their brand identity and product requirements. This flexibility allows companies to differentiate their products on the shelves, attracting consumers with unique and attractive packaging.

In addition to its practical benefits, the yogurt cup injection mould is also designed with sustainability in mind. Many modern moulds are made from durable materials that can withstand repeated use, reducing waste and the need for frequent replacements. This not only helps to minimize environmental impact but also reduces production costs over time.

As the demand for yogurt and other dairy products continues to grow, the importance of the yogurt cup injection mould cannot be overstated. These moulds are becoming increasingly sophisticated, incorporating advanced technologies to further enhance production efficiency and product quality. Whether you are looking to improve your existing production process or to enter the yogurt market for the first time, the yogurt cup injection mould is a valuable tool that can help you achieve your goals.

The yogurt cup injection mould is a vital component of modern food packaging. Its precision, efficiency, customization options, and sustainability make it an essential tool for producers of all sizes. As technology continues to advance, we can expect the yogurt cup injection mould to become even more sophisticated, helping to drive innovation and efficiency in the food packaging industry.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness