Plastic pallet moulds are critical tools used in the production of plastic pallets

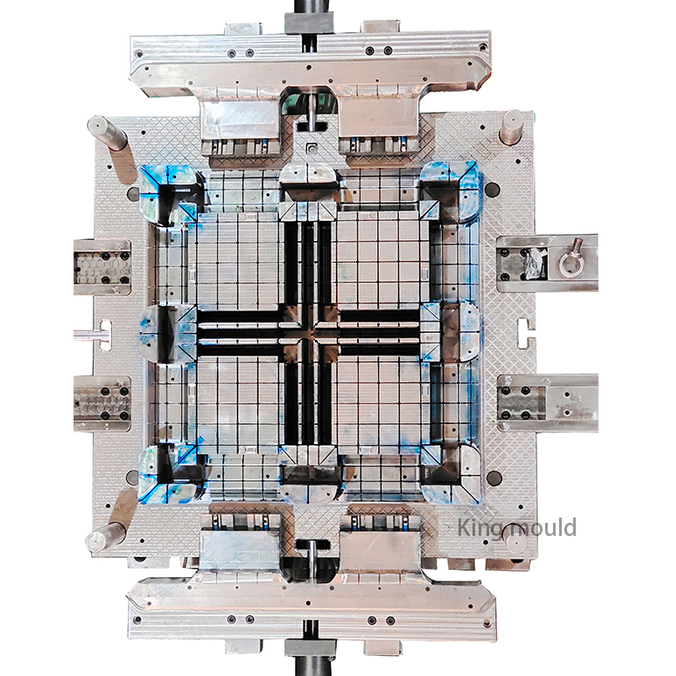

Plastic pallet moulds are critical tools used in the production of plastic pallets, which are commonly used in industries for the transportation and storage of goods. These moulds are designed to shape and form plastic materials into durable, uniform pallets that are essential for logistics, warehousing, and shipping applications. The role of plastic pallet moulds goes beyond simple shaping; they contribute significantly to the efficiency, strength, and cost-effectiveness of pallet production.

A plastic pallet mould typically involves a multi-step process. First, raw plastic material, often in the form of pellets or granules, is melted and injected into the mould cavity. The material is then cooled and solidified, taking the shape of the desired pallet. The mould itself is precisely engineered to produce pallets that meet specific standards, such as load capacity, durability, and dimensions. The mould must also be designed to accommodate the material’s properties, ensuring that the final product maintains structural integrity under heavy loads and varying conditions.

One of the key advantages of plastic pallets over traditional wooden pallets is their ability to withstand harsher environmental conditions. Plastic pallet moulds produce pallets that are resistant to moisture, chemicals, and pests, unlike wooden pallets that can absorb moisture and become breeding grounds for bacteria and insects. Furthermore, plastic pallets do not splinter or crack, providing a safer alternative for handling goods in warehouses and transportation environments.

The durability and long lifespan of plastic pallets contribute to their cost-effectiveness. Although plastic pallets may have a higher upfront cost compared to wooden alternatives, their extended durability and ability to be reused many times often lead to lower overall costs in the long run. Additionally, plastic pallets are often lighter than wooden ones, making them easier to handle and reducing shipping costs.

Plastic pallet moulds are also designed with efficiency in mind. With modern injection moulding technology, manufacturers can produce large volumes of pallets in a relatively short amount of time. The use of high-quality materials and advanced moulding techniques ensures consistent production quality, reducing defects and improving product reliability. This efficiency is especially important for industries that require high volumes of pallets for their logistics and distribution operations.

In conclusion, plastic pallet moulds are an essential part of the manufacturing process that produces durable, reliable, and efficient plastic pallets. Their role in shaping plastic material into a usable product is critical for industries that rely on pallets for transporting goods. The continued evolution of plastic pallet mould technology is likely to enhance the performance and cost-effectiveness of plastic pallets even further, offering businesses an increasingly sustainable option for material handling.

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness