Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Δημοσιευμένα 2025-01-15 07:46:22

0

1χλμ.

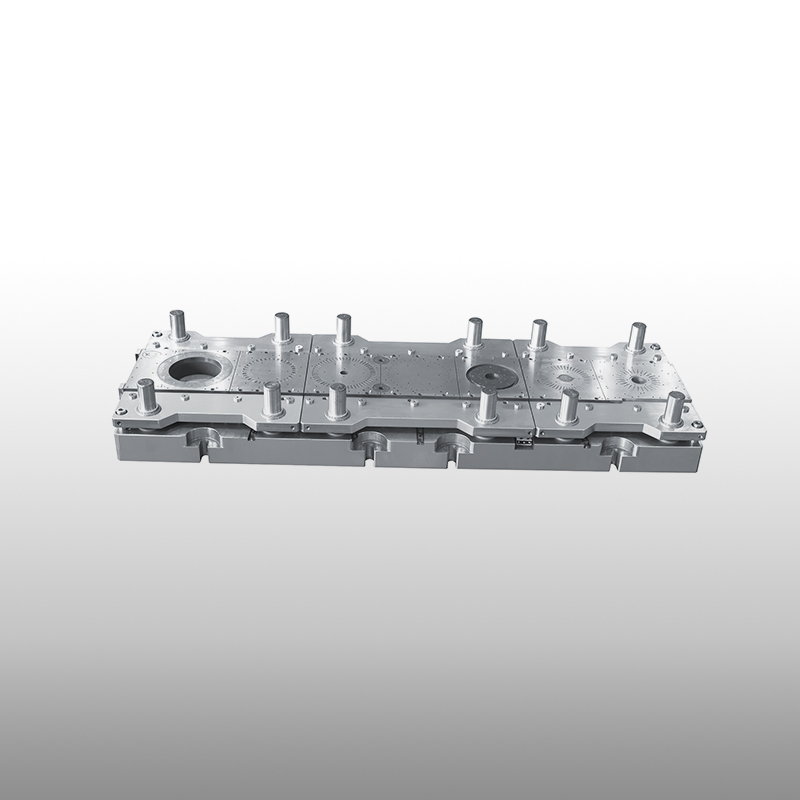

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Αναζήτηση

Κατηγορίες

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Διαβάζω περισσότερα

The Different Shapes and Sizes Available for Rubber Magnets Manufacturers

Magnetic tape is a type of Rubber Magnets Manufacturers that combines the flexibility of a...

Assessing the Weight-Carrying Abilities of Rectangular Hollow Out Storage Baskets

Rectangular Hollow Out Storage Baskets are a common sight in homes and offices, prized for their...

The Evolution of Rubber Extruder Technology: A Comprehensive Overview

In the manufacturing and processing industries, rubber plays an essential role due to its unique...

Leather Living Room Furniture: A Guide to Choosing the Perfect Fit

Leather living room furniture exudes timeless elegance and sophistication, making it a...

katrina lim viral kiffy www xmyclip com watch website jwz

🌐 CLICK HERE 🟢==►► WATCH NOW

🔴 CLICK HERE 🌐==►► Download Now...