Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posté 2025-01-15 07:46:22

0

1KB

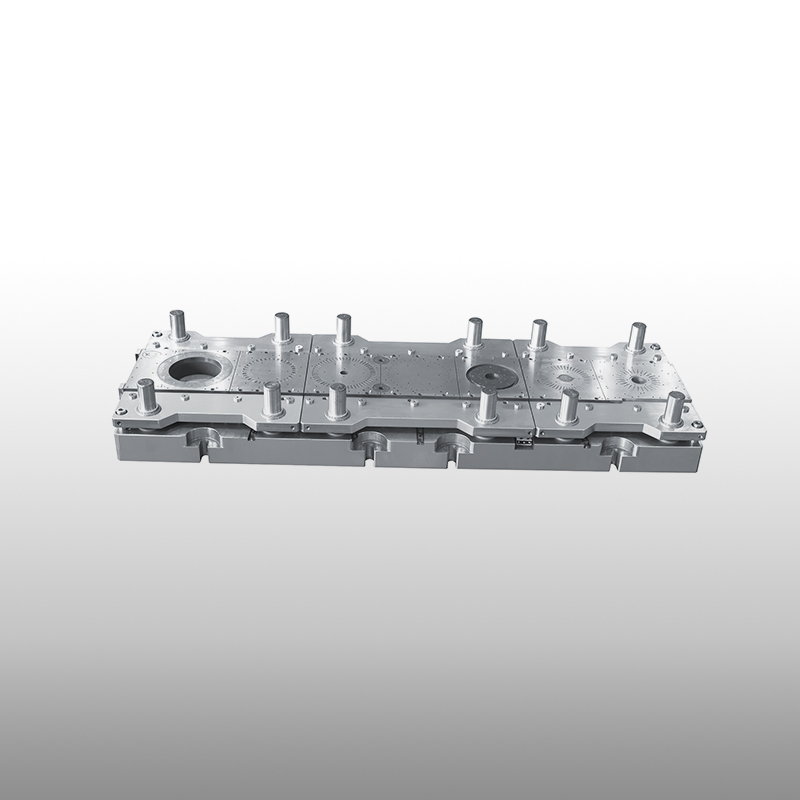

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Rechercher

Catégories

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Lire la suite

Exploring the Power of Ndfeb Countersunk Magnets for Precision Applications

Ndfeb (Neodymium-Iron-Boron) magnets have become increasingly popular in various applications due...

The Versatility of Flat Makeup Bags: From Casual to Formal

One of the standout advantages of Flat makeup bags is their space-saving design. These bags...

Trends in the Home Appliance Mould Market

The increasing consumer demand for personalized and customized home appliances is another...

FULL VIDEO: Melissa gate video (18+) videos de melissa gate karina garca yina calderon erome gqi

🌐 CLICK HERE 🟢==►► WATCH NOW

🔴 CLICK HERE 🌐==►► Download Now...

Strategy Consulting Market Size, Share | Growth Trends - 2035

Strategy Consulting Market Overview:

The Strategy Consulting Market is witnessing significant...