Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Сообщение 2025-01-15 07:46:22

0

1Кб

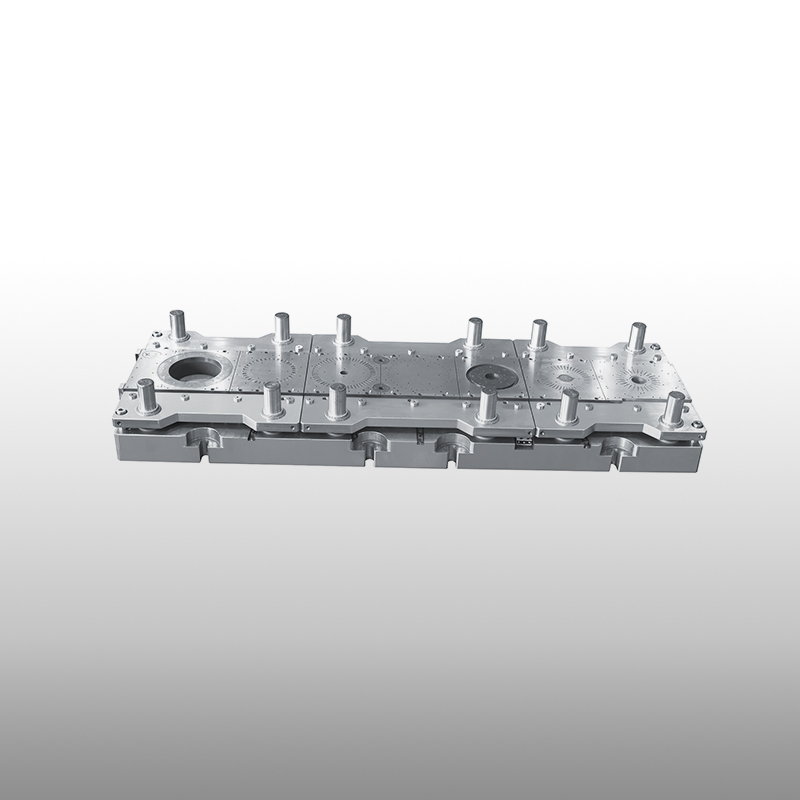

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Поиск

Категории

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Больше

Divide Forged Wheels: Aesthetic and Functional Value

When upgrading a vehicle, Divide Forged Wheels offer both visual appeal and functional...

The Safety Aspects of Invisible Floor Drain

Invisible floor drains are a modern solution that has been gaining popularity in both...

Is Shruti Sharma the Diljit Meme Girl?

Yes, as per social media buzz, Shruti Sharma is indeed the Diljit Meme Girl who has taken the...

no matter where I am in the world Bvlgari so that I feel like

the creative director is markedly joyful about her collared shirts a time machine back to the...

Clip 18+ viraly lol hindi viraly lol viraly.lol viraly. lol viraly. lol viral lol viral lol video mdo

🌐 CLICK HERE 🟢==►► WATCH NOW

🔴 CLICK HERE 🌐==►► Download Now...