Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Posted 2025-01-15 07:46:22

0

1K

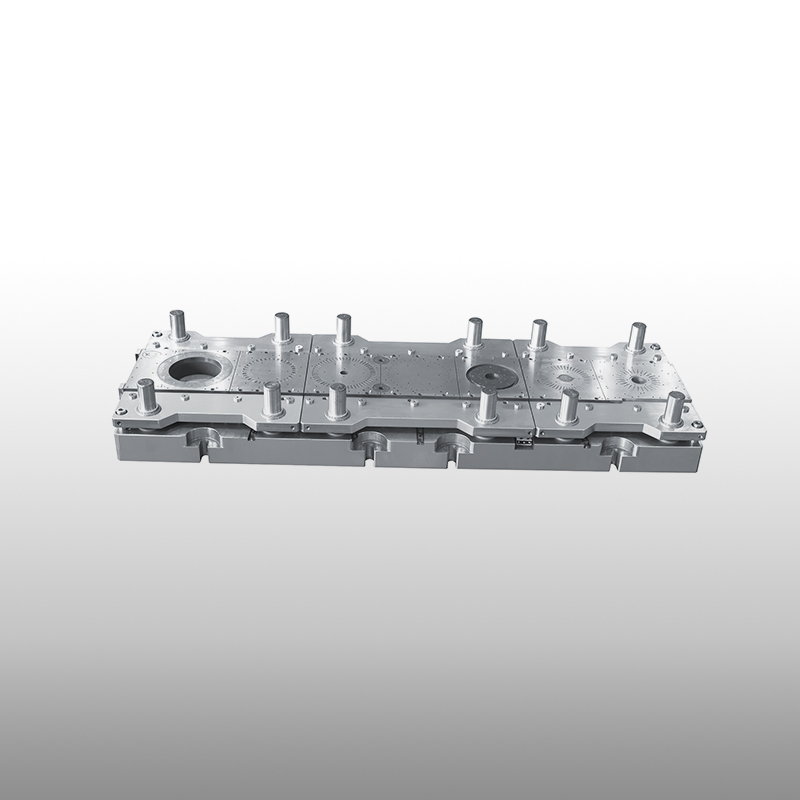

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Buscar

Categorías

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Read More

Winter Collection Golden Goose Scarpe Sconto just released two days

Our Slide sneakers take you straight to Venice Beach, between an ollie and a kickflip. Over the...

Selecting the Right Air Compressor: A Guide for HVAC Professionals

Air compressors factory are integral to a wide range of industries, from manufacturing and...

Dominate Black Ops 6 with the Best Essex Model 07 Loadouts: A COD BO6 Boosting Guide

Call of Duty: Black Ops 6 is assertive to bear a blood-tingling multiplayer experience, and...

Brushless vs. Brushed: Choosing the Right Motor for Your Wheelchair

Wheelchair Brushed Reduction Motors have been a traditional and widely used choice for powering...

U4GM - 6 Real-Money Trading Risks WoW Mop Classic

In the world of WoW Mop Classic, one of the most controversial topics that players often face is...