Quality Control in Motor Core Stamping: Ensuring Precision and Reliability

Postado 2025-01-15 07:46:22

0

1KB

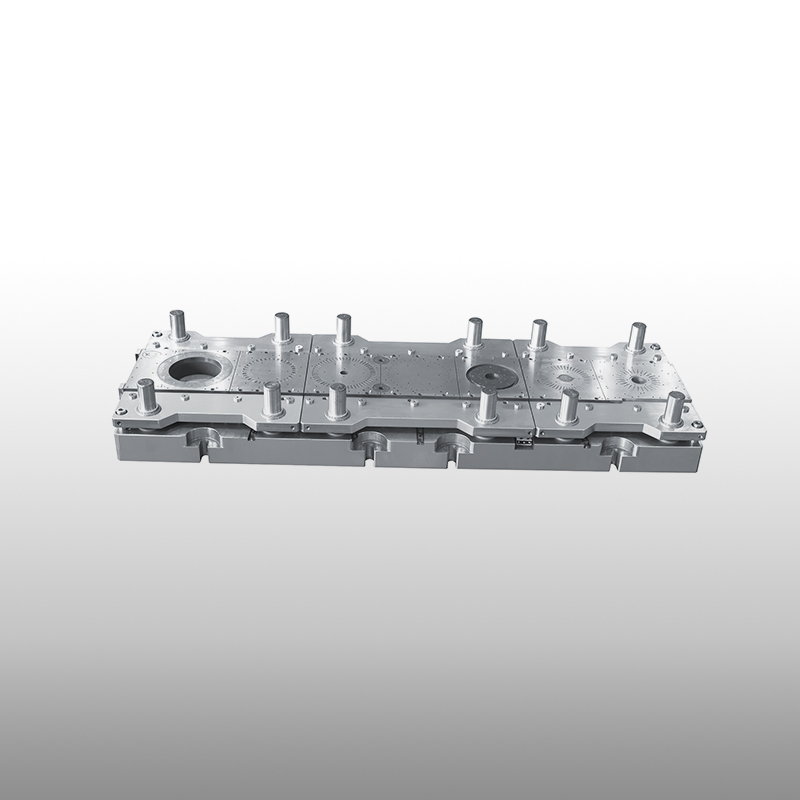

The motor core stamping process involves the fabrication of stator and rotor cores, which are essential components in electric motors. Given the complexity of these components, maintaining high-quality standards throughout the stamping process is crucial. Quality control begins with the selection of raw materials, which must meet specific criteria to ensure they can withstand the demands of the final application. The properties of the materials used in motor core stamping directly affect the performance and efficiency of the motor, making material inspection a fundamental step in the quality assurance process.

Pesquisar

Categorias

- Art

- Causes

- Crafts

- Crypto

- Dance

- Drinks

- Defi

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

Leia mais

How to Choose the Right Large Garden Furniture Set for Your Needs?

A large garden furniture set has the potential to significantly upgrade the aesthetic and...

Rolling Smart: U4GM’s Guide to Monopoly Go Success

Monopoly Go elevates the classic board game experience with a dynamic digital twist, engaging...

Can a 40oz Insulated Tumbler Withstand Drops, Scratches, and Daily Wear?

When investing in a reusable drinkware product, durability is one of the most critical factors to...

Gold is essential for advancing in the Elder Scrolls Online game

Elder Scrolls Online (ESO) is an expansive MMORPG that immerses players in the rich lore and...

Video Bocor! cikgu cctv wiring leak & video cikgu cctv wiring viral video cikgu dan abang wiring maz

🌐 CLICK HERE 🟢==►► WATCH NOW

🔴 CLICK HERE 🌐==►► Download Now...